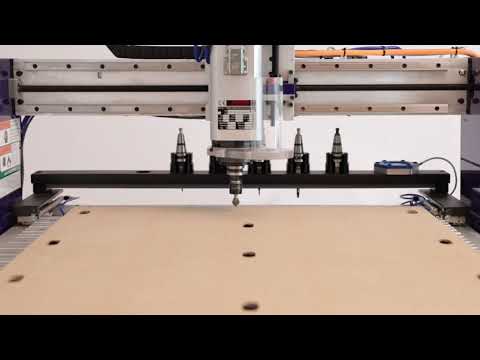

The ShopBot Desktop MAX ATC takes the precision and reliability of our Desktop MAX CNC and accelerates your machining process with the addition of a 7-tool automatic changer. With an automatic tool changer, not only can you skip the pauses in your work for bit changes, but your bit length measurements are stored permanently from cut to cut, ensuring accuracy in multi-bit jobs.

This desktop CNC has a 36" x 24" work area and is available with a t-slot aluminum deck or a vacuum hold down deck. A rotary indexer can be used with the machine, and for oversized material, the tool bar can be easily removed to temporarily convert the tool to a quick manual tool-change machine. Take full advantage of the efficiency that digital fabrication and small shop robotics provide with the ShopBot Desktop MAX ATC.

The Desktop MAX ATC with Aluminum Deck (general purpose deck) comes standard with an attached MDF spoil board and is considered our most versatile deck option for a wide variety of machining options. Because the Desktop MAX ATC is completely open underneath and the aluminum deck can be partially or completely removed, you can add widely available dovetailing or end-milling attachments, or add our lower deck option for additional Z travel.

The Desktop MAX ATC with Universal Vacuum Hold Down Deck kit includes a plywood plenum, MDF spoil board, and the Fein Turbo II Vac for quick hold down of sheet goods. This deck option is not optimal for cutting small parts, but is well-suited for large parts without additional hold down from screws, nylon nails, or tabs.

See the Hold Down at a Glance chart for more information on hold down.

Looking to purchase 10 or more tools? Ask us about our fleet pricing.

| 2 Deck Options: Aluminum “T” slot extrusion, with MDF spoil board [optional, removable] OR Universal Vacuum Hold Down Deck with Fein Turbo II Vac kit, with plywood plenum and MDF spoil board |

| Drive System: 4 motors with integral, Teflon-coated precision lead screw with anti-backlash technology on each axis(1X, 2Y, 1Z) |

| Integral guard and dust skirt |

| Cut Speed: 4 inches per second (100mm/sec) |

| Jogging Speed: 6 inches per second (150mm/sec) |

| Resolution: 0.00025” (.00635mm) |

| Electrical System Requirements: 120V @ 15Amps |

| Frame: Machined aluminum members that are bolted together |

| Linear Bearings: Fully supported precision linear guides and blocks on each axis |

| ShopBot Control System software to run your CNC |

| Each new ShopBot tool includes powerful design software to create CNC projects. |

| Support Resources and Documentation |

| Includes simple, quick-start set-up guide |

| Movement Area | 38” x 25” x 5” 970mm x 640mm x 127mm | ||

| Footprint | 48” x 39” x 30” 1220mm x 990mm x 760mm | ||

|

Nominal Cutting area and Total Movement Area refer to the areas that can be covered using a single z-axis.

Spindle VFD ts to the right side of the gantry |

|||

| Spindle | Teknomotor ATC41-ISO20 |

| Tool Holders | Seven-position tool bar standard |

| Zero Plate | Fixed-position Z-zero plate |

| Tool holder type | ISO20 tool holder with ER20 collet |

| XYZ Movement | 38” x 25” x 5” 965.2mm x 635mm x 127mm |

| Cutting Volume |

36” x 24” x 3.5”

914.4mm x 609.6mm x 88.9mm

35" x 23" x 8" (with lower deck option) 890mm x 584mm x 203mm (with lower deck option) [e.g. with 2” long cutter] |

| Footprint with Spindle |

48” x 39” x 30”(h)

[Spindle VFD fits to right side of gantry] |

| Weights |

127 lbs [no deck, no cutter]

194 lbs [total weight with aluminum deck and spindle] 234 lbs [total weight with universal vacuum hold down deck kit and spindle] |

| Crate dimensions | 44.5” x 55.75” x 37.5”, weight: 220 lbs, loading dock, forklift or lift gate service is recommended |

| Frame | Machined aluminum members that are bolted together |

| Collets |

Includes:

7: ISO20 tool holders 7: ER20 collets Note: Maximum collet size is 1/2" (ER20) |

| 2 Deck Options | Aluminum “T” slot extrusion, with MDF spoil board [optional, removable] OR Universal Vacuum Hold Down Deck with Fein Turbo II, plywood plenum and MDF spoil board |

| Linear Bearings | Fully supported precision linear guides and blocks on each axis |

| Drive System | 4 Motors with integral, teflon-coated precision lead screw with anti-backlash technology on each axis (2X, 1Y, 1Z) |

| Safety | Integral Guard and Dustskirt |

| Cut Speed | 4 inches per second (100mm/sec) |

| Jogging Speed | 6 inches per second (150mm/sec) |

| Resolution | 0.00025” (.00635mm) |

| Electrical System Requirements | 120V @ 15Amps |

| Air Requirements | 4 scfm at 90 psi of clean, dry, un-oiled compressed air. PORTABLE AIR COMPRESSORS ARE NOT RECOMMENDED, as they can have trouble maintaining this pressure reliably and have a reduced service life. |

| Maximum Bit Size | 1.5” diameter max, length 3” |

| Software | Software: ShopBot Control System software to run your CNC. Each new ShopBot comes bundled with two powerful software programs to create CNC projects. |

| Includes simple, quick start set-up guide |

While there are endless possibilities of what you can do with the ShopBot Desktop MAX ATC, here are a few examples of areas where people are putting their CNC tool to use:

Sign makers are using CNC for 3D carving, V-bit carving, profile contouring, fluting, and engraving. It also provides them with the opportunity to cut their own channel letter components, frames, posts, and borders in-house.

Learn more about Signmaking with CNC

High-volume furniture and millwork companies, as well as novice and master craftsmen, are embracing CNC technology. Craftsmen are quickly realizing that the CNC process doesn’t jeopardize their pieces' authenticity; it only adds to quality and uniqueness of the finished product.

Learn more about Woodworking with CNCWhatever size manufacturing business you have, success today is about agility. ShopBot tools give you the ability to accommodate shifting priorities.

Learn more about manufacturing with CNC .

No educational setting is complete without a ShopBot. Our digital fabrication tools take STEM learning to the next level.

Toll Free: 1-888-680-4466

Phone: 919-680-4800

Fax: 919-680-4900

ShopBot Tools, Inc.

3333-B Industrial Drive

Durham, NC 27704

USA

Office Hours

Monday–Friday: 9am–5pm EST

After Hours Tech Support

Monday–Friday: 5pm–9pm EST

Saturday–Sunday: 10am–5pm EST

Office Closure

ShopBot Tools, Inc. is closed New Year’s Day, Memorial Day, July 4th, Labor Day,

Thanksgiving Day and the following Friday, and Christmas Eve and Christmas Day.

Outside of normal office hours, we regularly check for support requests,

email and phone messages. To make sure we can get back to you as soon as possible,

leave a phone number or return email address where you will be available.